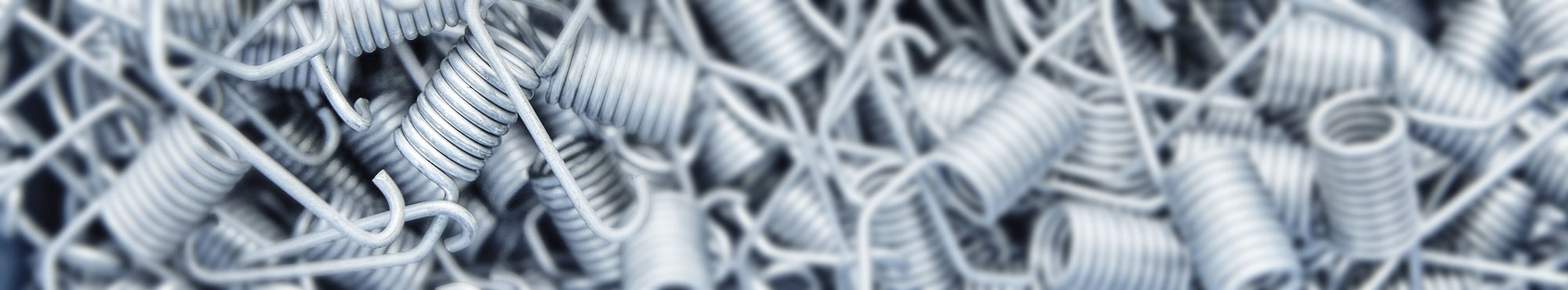

Torsion/leg springs

Helical springs used to transmit torque or to store torsional energy are referred to as torsion springs. Since the load is by and large always transmitted via the long legs at the end of the springs, they are also referred to as leg springs. The calculation and design of torsion/leg springs are standardised.

At S & P, torsion/leg springs are only cold-formed. Depending on the application, different materials (spring steel wire and spring wire made of non-rusting wires) are used.

At S & P, the two most common types of torsion/leg springs have one spring body or two spring bodies symmetrical to each other. Depending on the application, the leg can have different shapes.

The leg spring design depends on the available installation space, the spring absorption, the torsional energy to be stored and the connection to the machine component to be twisted.

-

Wire diameter d:

Min: approx. 1.5 mm

Max.: approx. 8 mm -

Leg length and leg shape:

Individual

Special versions and special dimensions are available by individual agreement.

S & P Federnwerk GmbH & Co. KG

An der Haselmauer 2

56472 Nisterau